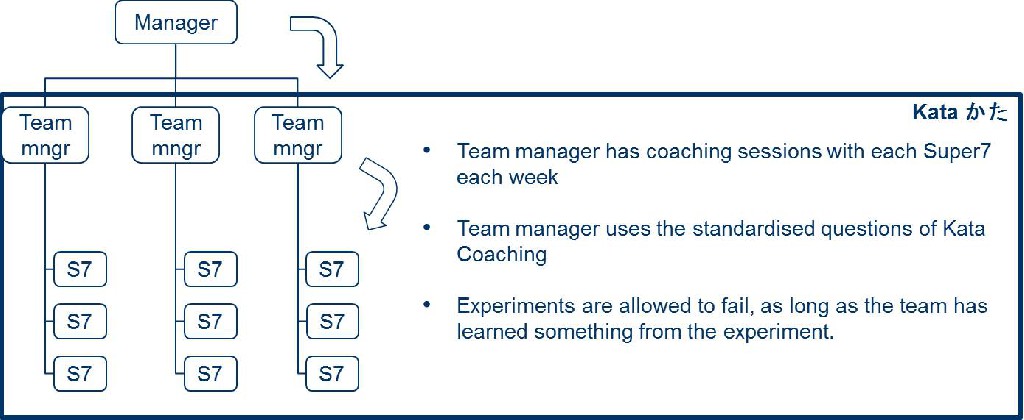

Can you run a bank with less management? If you would remove one layer of management from a large financial service organization – let’s say a bank – would that organization be less effective? And with two layers of management removed: would a bank need to be rescued with taxpayer’s money? My recent experience with customer focused, autonomous Lean teams at a Dutch retail bank have taught me: Super7 Operations (see my book: Super7 Operation – the Next Step for Lean in Financial Services) requires Less Management, More Delegating. It may be too much to claim that two layers of management can be removed, perhaps not even one entire layer, but the span of control of one manager can dramatically be increased. And yes, that means a lot less managers. So why is that, what type of management tasks are eliminated by using small autonomous lean teams?

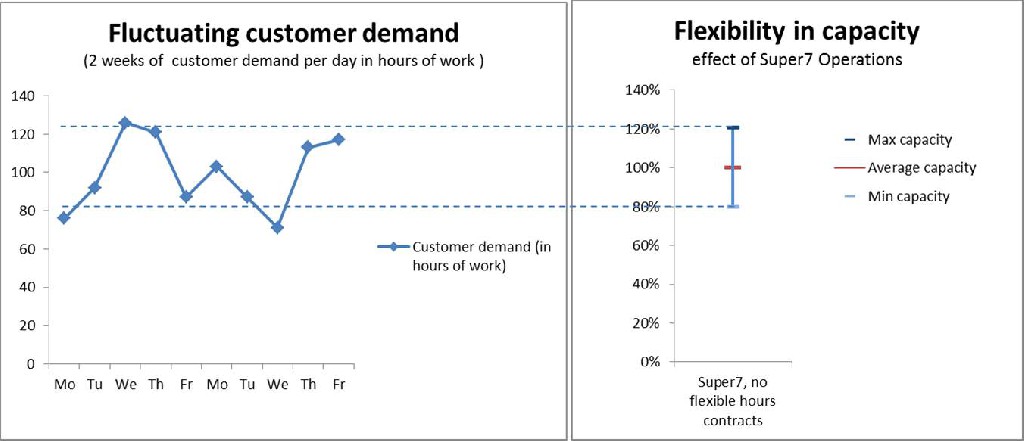

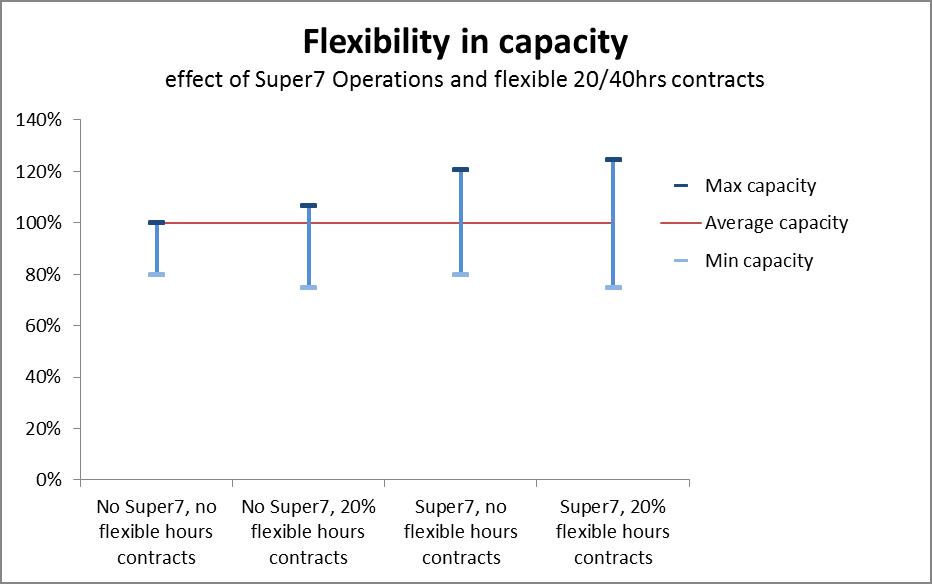

Less Capacity Planning

“Is it okay to take a day off next Tuesday?”. In the old days, managers spent a lot of time planning the capacity of the team. Especially in preparation of the holiday season or in the summer period. An autonomous Lean team will take care of this planning themselves. And they make sure that they have sufficient capacity to get the forecasted amount of work done.

Less Management of Inventory

Prior to Super7, work needed to be booked in an inventory management system, and the age of the inventory (when did we receive the customer request?) needed to be monitored and compared to the Service Level Agreement (SLA). Then, if the system says ‘Orange light, i.e. ‘we’ve got only one day left within SLA’, priorities needed to be reshuffled urgently to prevent ‘Red Light’ the next day.

Less Management of Assigning Work

Because there is a lot of work in inventory, team managers attempted to get the ‘best work streams’ assigned to their team. The norms for each work stream differed; moreover, not all norms were set as accurate.

Less Management of skills

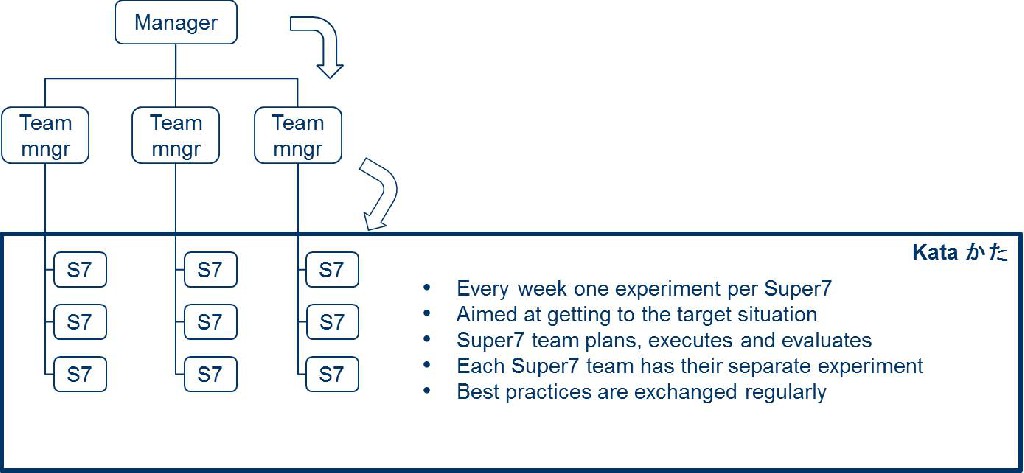

In the past, a Daily Production Meeting was held, in which the team managers, all together, determined which team would be doing which work streams the next day. In Super7’s, this whole circus isn’t needed. Each Super7 knows what work they will be doing: the same work every day, and all work that came in that day.

Less Management of Work In Progress

Before Super7, a manager needed to check the inventory system: is the work still waiting, or is it work-in-progress? A manager also needed to look in the report of the Daily Production meeting: where was the work assigned to? Finally, a request had to be distributed to the individual employees.

Let’s remove management layers!

Menno R. van Dijk.